|

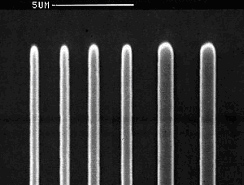

The LaserWriter pattern generator Planar

laser lithography and direct writing |

|

|

The LaserWriter system by MICROTECH is designed for the definition of

planar geometries and for surface diagnostics, in applications where maximum

resolutions down to 0.7 µm are required. The system transforms a laser beam

into a controlled writing tool for photolithographic mask fabrication or for

direct in situ processing on planar substrates. Besides

microlithographic applications, its optical apparatus and substrate motion

management are also well suited for surface inspection or diagnostics. Hence,

the same machine can be used first for producing a pattern and later for

inspecting the results. The patterns are generated by accurately moving the

target (mask or substrate) underneath a focused and scanning laser beam with

proper wavelength. The performance and cost of the system are optimised for

research and development or small/medium productions. Application fields Pattern generator LW405 specifications Picture gallery |

|

|

Application fields of the LaserWriter Microelectronics Integrated Optics Diffractive Optics Micromechanics Microcryogenics Hybrid circuits Flat panel displays Microwave Integrated Circuits (MICs) MultiChip Modules (MCM) Photovoltaics Photoelectrochemistry For

each application the proper LaserWriter configuration can be selected and

customised. |

|

|

The

in house availability of a LaserWriter system for microlithography

means: - cutting

down mask costs when developing new prototypes; - minimal

mask making times (masks are available just a few minutes after

patterning ends);

- possible

elimination of masks and mask aligner. For single or low quantity

prototypes it can be convenient to draw directly on the final substrate. This

possibility is also profitable when a clean room suitable for the use of a

mask aligner/exposer is not available: direct writing results in reduced

substrate handling, that is a reduction of microcontamination induced

defects. |

|

|

A GENERAL PURPOSE MICROTOOL Depending

on customer needs, the LASER WRITER system can also be configured as a

research or production tool for surface microprocessing, such as:

|

|

|

AN INSPECTION AND DIAGNOSTIC TOOL Both

laser and non laser applications can be developed for:

|

|

When

you need a discretionary 2-D process, why spend time with electronics,

mechanics, optics, high and low level programming, electrooptics? Concentrate

your efforts on the process, minimize development time and let MICROTECH take

care of the hardware. Is it expensive to buy and maintain? Major

characteristics of the LaserWriter are competitive price and reliability.

These are obtained by customizing the system and by carefully selecting and

sizing all its components, for years of maintenance-free use. Among

competitors' systems with similar performances, the LaserWriter is by far the

lowest priced. Note that commercially available systems from other

manufacturers are mostly oriented to high-volume microelectronic production. Therefore,

their performances - and prices as well! - match such target market. The

LaserWriter is designed and optimised for research and development

applications and for small/medium productions. Hence, while keeping the

precision patterning features available in alrger and much more research

centres or small/medium manufacturers. The

maintenance costs of the LaserWriter are also very low. The system is

designed to require virtually null maintenance over several years of use. Of

course, the natural aging of the laser source is unavoidable, but the refurbishment

timecan be easily predicted and laser replacement is typically a matter of

minutes. Which system configuration should be selected? One basic

LaserWriter model is available for microlithographic applications, with some

options. Such model is just the starting point for customisation. Its main

features are detailed in the specifications table. Note

our commercial approach as follows. When dealing with MICROTECH, the client

can choose between two procedures:

Each

system is driven by LaserDraw-2D, a MICROTECH proprietary software

package. Details

of typical patterns are reported in the 2-D

lithography picture gallery page. Are

you concerned for the limited floor space available? Place the

LaserWriter everywhere in your clean-room. The footprint of the latest

release of the system is just 65x65 cm, including drive electronics! Are

you concerned for system servicing? The hardware and software

modular design of the LaserWriter minimizes system downtime and makes

servicing or upgrading simple and quick. |

|